Photovoltaic bracket industry introduction

Release time:

Apr 03,2024

Industry background:

As the "skeleton" of photovoltaic power station, photovoltaic bracket is composed of hot galvanized carbon steel, zinc aluminum magnesium, aluminum alloy and other materials of steel and supporting accessories, easy to assemble and economic and durable. It is used to stabilize and support solar panels in a variety of scenarios, including rooftop, ground and agricultural, carport and a range of photovoltaic systems. The brackets are available in fixed, flexible and tracking types, the latter of which can be adjusted seasonally to optimize lighting. Steel is its main raw material, with the growth of photovoltaic installed capacity, the steel demand for the bracket is also rising. The increasing global demand for clean energy will further drive the expansion of the PV bracket market. In order to let the majority of people better understand the photovoltaic bracket market, green Ji new energy special collation of this article to the reader.

Photovoltaic bracket introduction:

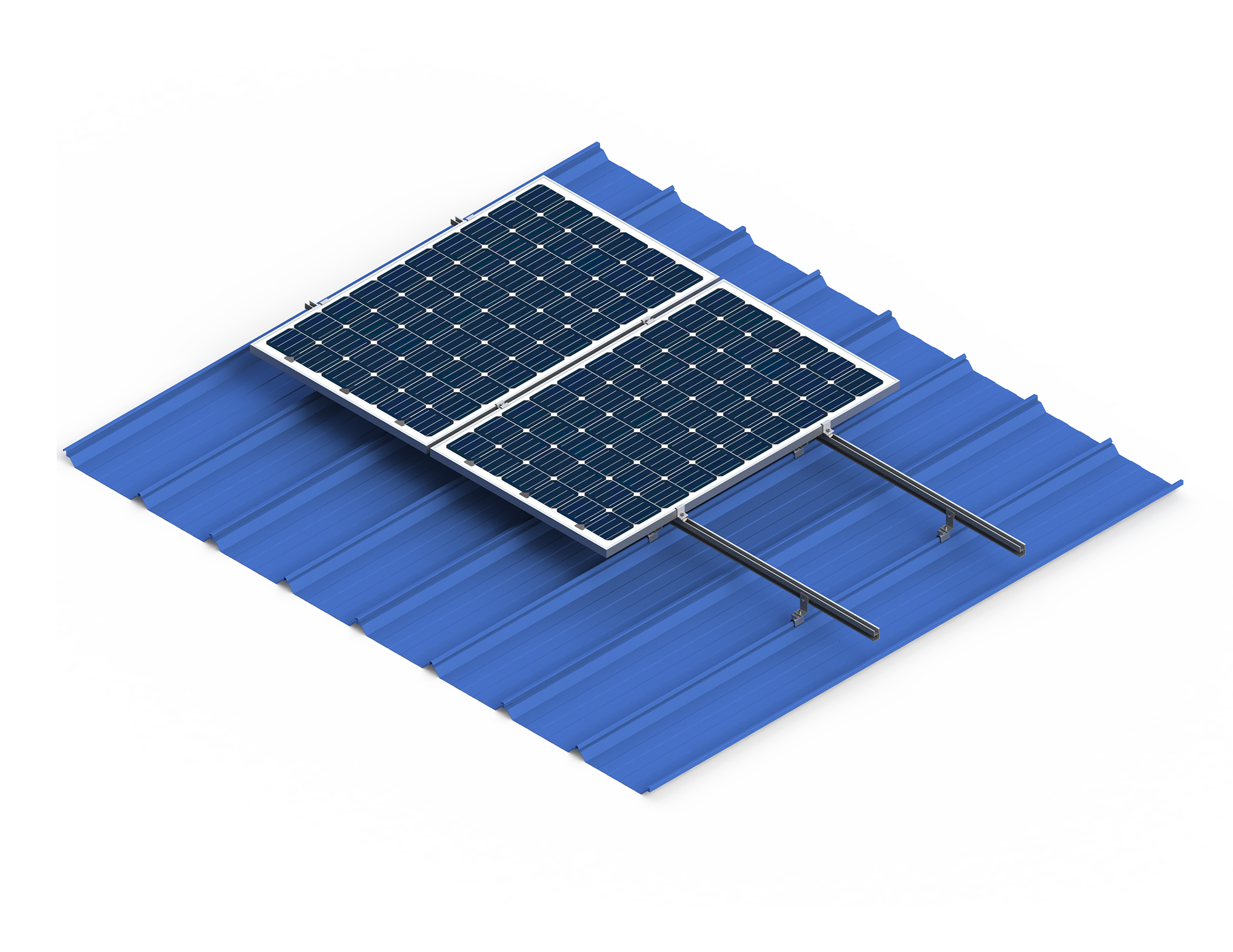

Photovoltaic bracket, also known as solar panel bracket, is an important facility for installing and supporting solar panels. It is the "skeleton" of photovoltaic power plants, providing stable and reliable support for photovoltaic modules to ensure that photovoltaic power plants can operate stably in a variety of environments. Photovoltaic brackets are usually made of zinc aluminum magnesium U-shaped steel or C-shaped steel and support connection accessories, which makes the bracket not only easy to handle and assemble, but also has the advantages of easy maintenance, long service life and low economic cost.

The main function of the photovoltaic bracket is to fix the photovoltaic module on the roof, ground, water and other photovoltaic power station application scenarios. According to the different application scenarios, photovoltaic supports can be divided into roof supports, ground supports, agricultural photovoltaic system supports, etc. For example, the rooftop photovoltaic power generation system is to install photovoltaic brackets and photovoltaic modules on the roof of the building, which is very common in urban buildings or places where the land is relatively tight, and can greatly reduce the requirements for the site. Ground photovoltaic power plants are usually built on the ground and consist of photovoltaic modules, bracket structures and electrical equipment, which is a clean, renewable and increasingly common way to build photovoltaic power plants. According to the installation method, the photovoltaic bracket can also be divided into fixed brackets and tracking brackets, fixed brackets are divided into ordinary fixed brackets and fixed adjustable brackets, and the component orientation is manually adjusted according to the light changes in different seasons.

In the manufacturing cost of photovoltaic brackets, raw material costs account for more than 70%, half of which comes from steel. Steel is the main raw material of photovoltaic support, and its consumption increases with the increase of installed capacity of photovoltaic power stations. The steel part of the photovoltaic bracket mainly includes beams, inclined beams, inclined braces, columns, inclined tie rods and other components, which are shaped steel as the main material, including C-shaped steel, Angle steel, H-shaped steel, etc. For example, in a photovoltaic power station project using a vertical 2*30 array, the steel consumption of one array reached 530.25KG.

As the global demand for clean energy increases, photovoltaic power generation as an important form of clean energy, its installed capacity continues to grow. This has led to the incremental demand for steel for photovoltaic brackets is also increasing. In China, for example, the new PV installed capacity in 2021 reached 54880MW, if all converted into steel, the new demand is about 2.08 million tons. In the future, with the continuous expansion of photovoltaic power stations, the steel demand for photovoltaic brackets will continue to increase.

In general, photovoltaic brackets are an important part of photovoltaic power stations, and their incremental steel demand increases with the increase in the installed capacity of photovoltaic power stations. In the future, with the further development and application of clean energy, the market demand for photovoltaic brackets will continue to expand.

Photovoltaic bracket type:

Photovoltaic bracket is a special equipment designed and installed in solar photovoltaic power generation system to support, fix and rotate photovoltaic modules. In order to achieve the best power generation efficiency of the photovoltaic power station, the photovoltaic bracket needs to be combined with the topography, climate and solar energy resource conditions of the construction site, and the photovoltaic modules are fixed in a certain orientation, arrangement and spacing. The photovoltaic bracket is divided into fixed bracket and tracking bracket according to whether the photovoltaic array can follow the change of the solar incidence Angle. Fixed bracket refers to the photovoltaic array can receive solar radiation in a fixed way of the bracket, the design of the bracket needs to be based on the local geographical location, environment, climate and other conditions, the bracket is maintained in favor of the maximum area to receive sunlight radiation Angle, fixed bracket is divided into ordinary fixed bracket and fixed adjustable bracket, for fixed adjustable bracket, Component orientation is manually adjusted according to seasonal light changes. The tracking bracket refers to the photovoltaic array can adjust the Angle of the solar Angle change bracket, compared with the fixed bracket, the tracking bracket production process more electronic control design, drive touch, supporting assembly of these three processes, mainly divided into flat single-axis tracking bracket, oblique single-axis tracking bracket and dual-axis tracking bracket, using the tracking bracket to establish a photovoltaic power generation system, Its component orientation can be automatically adjusted according to the lighting state, which makes it suitable for complex terrain, and more used in centralized photovoltaic installations.

Pv bracket cost structure:

In the cost composition of the entire photovoltaic power generation system, the photovoltaic bracket and its installation cost accounted for 16.3% of the investment cost of the power station, second only to the photovoltaic module and its installation cost. Photovoltaic fixed bracket and tracking bracket include raw materials, external galvanizing costs, manufacturing costs and labor costs, because the tracking bracket contains rotary deceleration device, electric control box and matching intelligent control system, at the same time, the production difficulty of the tracking bracket is relatively higher, labor and manufacturing costs have increased accordingly, resulting in higher production costs. In the production cost of fixed bracket and tracking bracket, raw materials accounted for the highest proportion, more than 60%, in addition to raw materials, outsourcing galvanized costs accounted for relatively high in the production cost, labor costs and manufacturing costs accounted for relatively low in the production cost; At the same time, the tracking bracket increased the drive part, and the cost item also increased the rotary reduction device and the electric control box, accounting for 12.1% and 9.9% of the production cost, respectively. Limited by the production cost, the unit price of the tracking bracket is often about 2 times that of the fixed bracket, and the average price of the tracking bracket in China in 2021 is about 0.57 yuan /W, and the average price of the fixed bracket is about 0.26 yuan /W.

Photovoltaic bracket market status:

Tracking brackets can achieve higher power generation efficiency than fixed brackets, but due to higher costs and reliability problems, the market share is still at a low level. At present, the penetration rate of China's tracking bracket is low, the demand for fixed bracket in 2021 is 46868MW, the demand for tracking bracket is 8012MW, the penetration rate is only 14.6%, lower than the international average level of 37%, but also far lower than the level of Europe and the United States, the penetration rate of tracking bracket in Europe and the United States is maintained at more than 50%. Since 2016, driven by the leader plan, the penetration rate of domestic tracking brackets has increased significantly, but after 2019, the reduction of tracking bracket projects in the leading plan and the existence of power consumption problems in some parts of the country have led to a decline in penetration. From the perspective of the competitive pattern of photovoltaic brackets, the industry shows a clear trend of head concentration, in 2021, CR3, CR5, CR10 respectively reached 42.1%, 601.%, 81%, of which CR5 and CR10 hit a new high in six years, Jiangsu Guoqiang Xingsheng, Zhongxinbo, Xingrun Hengxin are the top three manufacturers of photovoltaic brackets in China. The global shipments of its photovoltaic brackets were 11,950 MW, 6518MW and 5625MW, respectively.

Photovoltaic support equipment steel should have the performance:

Solar photovoltaic bracket steel performance requirements are strict, solar photovoltaic bracket equipment steel should have the following properties:

Tensile strength and yield point

The high yield point can reduce the section of the steel component, reduce the structural weight, save steel, and reduce the overall project cost. High tensile strength can increase the overall safety reserve of the structure and improve the reliability of the structure.

Plasticity, toughness and fatigue resistance

Better plasticity can make the structure produce large deformation before failure, so that people can find and take remedial measures in time. Better plasticity can also adjust the local peak stress, itself solar panel installation often in order to adjust the Angle, the use of forced installation, and plasticity can make the structure produce internal force redistribution, so that the structure or some of the original stress concentration part of the stress tends to be uniform, improve the overall bearing capacity of the structure. Better toughness can make the structure absorb more energy when it is damaged under external impact load, especially the desert power station and roof power station with large wind, the wind vibration effect is obvious, and the toughness of steel can effectively reduce the risk degree. Better fatigue resistance can also make the structure have a strong ability to resist alternating repeated wind loads.

Processability

Good workability includes cold workability, hot workability and weldability. The steel used in the photovoltaic steel structure is not only easy to process into various forms of structures and components, but also requires that these structures and components do not have excessive adverse effects on strength, plasticity, toughness and fatigue resistance due to processing.

Service life

Since the design service life of solar photovoltaic system is more than 20 years, good corrosion resistance is also an important indicator to measure the quality of the support system. If the life of the bracket is short, it is bound to affect the stability of the entire structure, resulting in an extension of the investment payback period and a reduction in the life of the entire solar photovoltaic system.

Future photovoltaic trends affecting the stent:

1, the increase in market demand for photovoltaic bracket is one of the important auxiliary materials of photovoltaic, its performance will directly affect the power generation efficiency and investment efficiency of photovoltaic, its installed demand is directly driven by the new installed PV. Photovoltaic power generation is one of the important clean energy utilization methods to achieve the goal of carbon peak and carbon neutrality in China, according to the "14th Five-Year Plan" renewable energy development Plan, China's renewable energy power generation will account for 50% of the total electricity consumption increase in the society during the 14th Five-Year Plan, "carbon peak action Plan before 2030" plans that the cumulative installed capacity of photovoltaic and wind power will reach 1200GW in 2030. The cumulative installed capacity of wind power and photovoltaic will nearly double in 2021. In 2022, the first batch of large-scale wind power bases in China has been built, which will promote the significant growth of photovoltaic installed capacity, and then promote the rapid growth of photovoltaic support shipments. In 2022, China's new photovoltaic installed capacity of 87.41GW, an increase of 59.27%, compared with 2021 to achieve substantial growth, photovoltaic support shipments will also achieve substantial growth. According to the forecast of CPIA, in 2030, China's photovoltaic installed capacity is 120GW in a pessimistic state and 140GW in an optimistic state, and China's photovoltaic installed capacity will grow year by year in the future, which will also drive the demand for photovoltaic brackets to grow year by year.

2, distributed photovoltaic widely used Distributed photovoltaic usually refers to the use of distributed resources, installed on a small scale, arranged near the user of the power generation system, mainly refers to residential photovoltaic and commercial photovoltaic; Concentrated photovoltaic refers to the concentrated construction of photovoltaic power stations in deserts, Gobi, mountains, water and other sites, and the power obtained is directly incorporated into the national grid, and the national grid supplies long-distance loads through access to high-voltage transmission systems. With the continuous improvement of photovoltaic power generation technology, the reduction of power generation costs and the increase of policy support, such as the implementation of distributed photovoltaic construction projects in the whole county, distributed photovoltaic has become the main force of new photovoltaic installations. In China, for example, driven by the "photovoltaic +" policy in 2019, the new installed capacity of distributed photovoltaic in the country reached 11.5GW, an increase of 17.4% year-on-year. In 2020, the installed capacity of distributed PV reached 22.78GW, an increase of 98.6%. Distributed photovoltaic is usually used for fixed brackets, the widespread use of distributed photovoltaic brackets will bring about an increase in the demand for fixed brackets, which may lead to the stagnation or even decline in the penetration rate of photovoltaic brackets, which deviates from the development trend of international and European and American regions.

3. Prices keep falling

In recent years, under the needs of the photovoltaic industry to reduce costs and increase efficiency, the cost of photovoltaic power generation has been declining, mainly for the following three reasons: First, the scale of the photovoltaic industry continues to expand, the production volume has increased significantly, with the expansion of the production scale, the manufacturing cost of photovoltaic equipment has also been reduced, the scale effect brought by large-scale production can reduce the production cost of materials, components and equipment. The second is technological progress, photovoltaic technology continues to innovate and progress, new materials, processes and equipment have been introduced, improving the efficiency and performance of photovoltaic power generation systems. The third is market competition: the photovoltaic industry is highly competitive, various enterprises in order to compete for market share and profit space, constantly innovate, improve production efficiency and reduce costs, market competition has promoted technological progress and manufacturing process improvement, thereby reducing the cost of photovoltaic power generation system. With the further promotion of technological progress and market competition, the cost of photovoltaic power generation will continue to reduce, providing broader prospects for the development of renewable energy, photovoltaic power generation will be widely used and promoted worldwide. Photovoltaic bracket as an important auxiliary material of photovoltaic, in the context of the overall cost of photovoltaic, the cost of photovoltaic bracket will gradually decline, and the price of photovoltaic bracket will continue to decline. In 2021, the average price of China's tracking bracket is about 0.57 yuan /W, and the average price of fixed bracket is about 0.26 yuan /W. According to CPIA's forecast, by 2025, the average price of China's tracking bracket will fall to 0.46 yuan /W, and the average price of fixed bracket will be about 0.24 yuan /W.

New demand for steel for photovoltaic brackets:

The raw materials of photovoltaic brackets are basically steel, mainly including beams, inclined beams, inclined braces, columns, inclined tie rods and other components, with shaped steel as the main material, including C-shaped steel, Angle steel, H-shaped steel, some brackets also use steel pipes and square rectangular pipes. Wang Min and He Wenjun in the article "Comparison of the amount of steel used in the support for horizontal and vertical arrangement of photovoltaic modules", taking a 30MW photovoltaic power station project in Vietnam as an example, the photovoltaic support for horizontal and vertical arrangement of photovoltaic modules was calculated and the steel amount was analyzed. In this photovoltaic power station project, 60 photovoltaic modules are designed as an array with an installed capacity of 22.2KW, including a vertical 2*30 horizontal array and a 4*15 array. The average total steel weight of an array is 562.19kg, among which the beam and inclined beam are C-shaped steel with a weight of 473.48kg, and the column is made of steel pipe. The weight is 65.43 kg, and the Angle steel is used for the inclined brace and the inclined column, and the weight is 23.28 kg. According to the above data, it can be estimated that the average support steel consumption per MW photovoltaic installed capacity is 25.33 tons, of which C-type steel is 21.33 tons, accounting for 84.22%, steel pipe is 2.95 tons, accounting for 11.64%, Angle steel is 1.05 tons, accounting for 4.14%. In 2022, China's new photovoltaic installed capacity is 87,408MW, if all converted into steel, the new steel demand for photovoltaic brackets in 2022 is 2,213,500 tons.

According to CPIA forecast, from an optimistic point of view, from 2023 to 2027, the global photovoltaic new installed capacity will increase from 330GW to 516GW, CAGR of 6.59%, the average annual new installed capacity is 406GW, the new steel demand is 10.284 million tons, of which the C-type steel is 8.662 million tons. Steel pipe is 1.1971 million tons, Angle steel is 425,800 tons; China's new PV installed capacity will increase from 120GW to 140GW, CAGR of 2.23%, the average annual new installed capacity is 127GW, the new steel demand is 3.216,900 tons, of which 2.709,300 tons of C-type steel, 374,400 tons of steel pipe, Angle steel is 133,200 tons. From the pessimistic situation, the global photovoltaic new installed capacity will increase from 280GW to 436GW, CAGR of 6.53%, the average annual new installed capacity is 343.8GW, the new steel demand is 870.85 million tons, of which C-type steel is 7334,300 tons, steel pipe is 1,013,700 tons, Angle steel is 360,500 tons; China's new PV installed capacity will increase from 95GW to 120GW, CAGR of 3.39%, the average annual new installed capacity is 104GW, the new steel demand is 2,634,300 tons, of which C-type steel is 8,661,200 tons, steel pipe is 1,197,100 tons, Angle steel is 425,800 tons.

In the production cost of photovoltaic bracket, the proportion of raw materials is the highest, and the raw materials are basically steel, and the future development of photovoltaic bracket will have a certain impact on the incremental demand for steel. Photovoltaic bracket is one of the important auxiliary materials of photovoltaic, photovoltaic future development trend will directly affect the demand for photovoltaic bracket, the growth of market demand will directly promote the growth of photovoltaic bracket shipments, the wide application of distributed photovoltaic may cause the penetration rate of the bracket to stall or even decline, photovoltaic overall cost reduction and efficiency demand will make the unit price of photovoltaic bracket continue to decline. Overall, the future shipment demand for photovoltaic brackets will continue to grow with the installed demand for photovoltaic, which will drive the incremental demand for steel. From the optimistic point of view, from 2023 to 2027, the average annual new installed capacity of global photovoltaic is 406GW, and the new steel demand is 10.284 million tons; The average annual installed capacity of PV in China is 127GW, and the new steel demand is 3.216,900 tons. From the pessimistic situation, the global photovoltaic average annual new installed capacity is 343.8GW, the new steel demand is 8.7085 million tons, China's photovoltaic average annual new installed capacity is 104GW, the new steel demand is 2.6343 million tons.

Next:

Related News