The Specific Application Of Photovoltaic Brackets

Release time:

Apr 15,2024

Photovoltaic bracket refers to the support structure that arranges photovoltaic modules in a certain orientation and Angle and fixes the spacing according to the specific geographical location, climate and solar energy resource conditions of photovoltaic power generation system construction. As an important part of photovoltaic power generation system, photovoltaic support directly affects the operation safety, damage rate and construction investment of photovoltaic modules. Choosing the right photovoltaic bracket can not only reduce the project cost, but also reduce the later maintenance cost. Photovoltaic brackets can be divided into three categories: fixed, adjustable Angle and automatic tracking, and the connection mode is generally welded and assembled in two forms. Among them, the fixed bracket can be divided into roof bracket, ground bracket and water bracket. The automatic tracking bracket is divided into single-axis tracking bracket and dual-axis tracking bracket. Table 1-2 lists the specific categories of photovoltaic supports.

Table 1-1 Categories of photovoltaic supports

1, fixed bracket

The fixed bracket is also called the fixed Angle bracket, and the component Angle and orientation can not be adjusted after the bracket is installed. Fixed bracket is divided into roof class, ground class and water class.

2. Roof bracket

The roof bracket is generally divided into three categories: color steel plate roof bracket, inclined roof (tile roof) bracket and flat roof bracket.

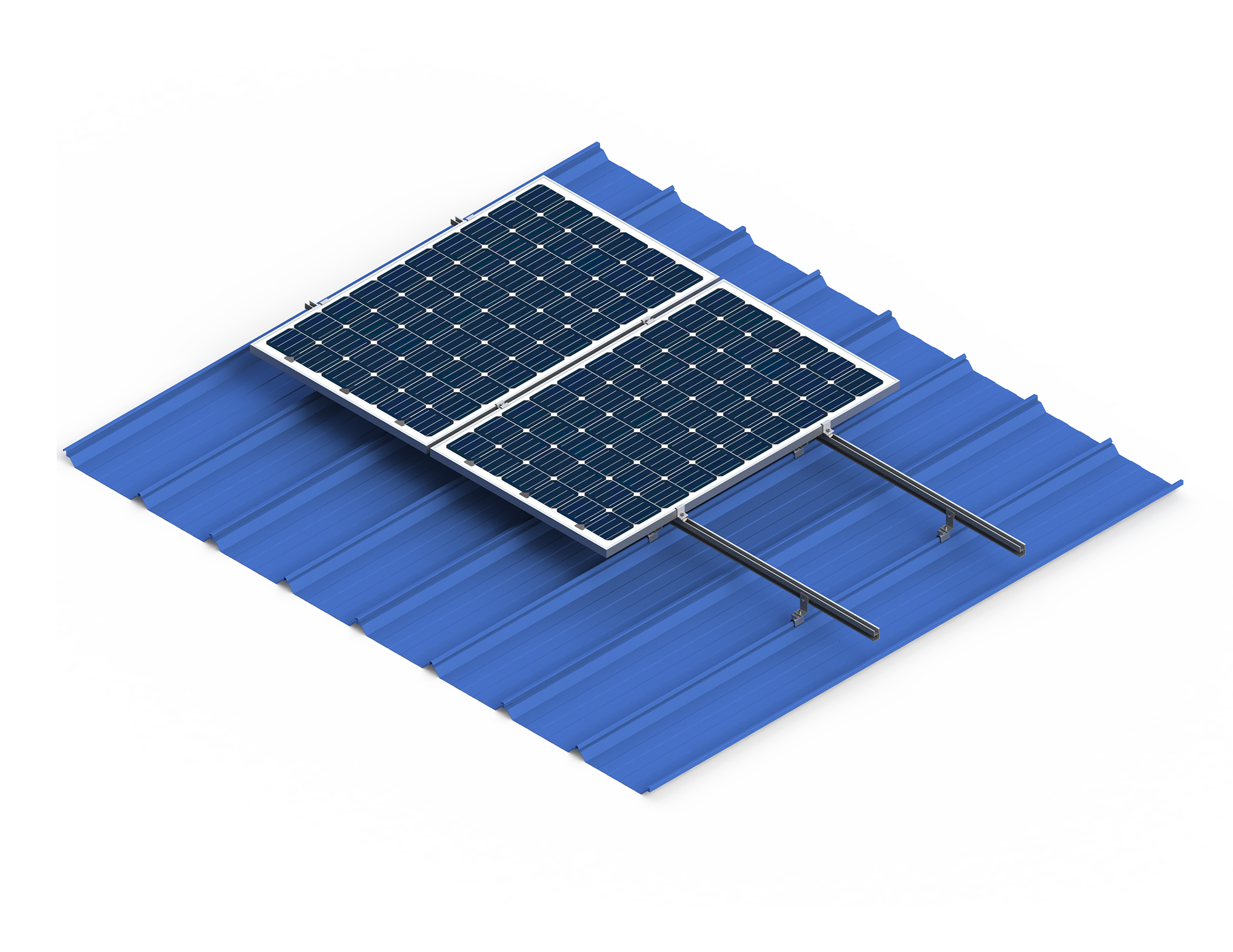

Color steel plate roof bracket is mainly composed of color steel plate fixture or fixed parts, guide rail (beam), component press, guide rail connector, bolt washer, slide nut, etc., as shown in Figure 1-1.

The inclined roof bracket is mainly composed of the roof fixing hook, guide rail (beam), component press block, guide rail connector, bolt washer, nut slide and so on. Figure 1-2 shows the structure of the common fasteners of the inclined roof support.

The above two kinds of brackets are generally finished C-type steel or aluminum alloy as the main support structural parts, with the advantages of fast assembly and disassembly, no welding, uniform anti-corrosion coating, good durability, fast installation speed, beautiful appearance and so on.

The flat roof bracket is similar to the ground bracket structure, generally using concrete foundation or concrete counterweight block as the bracket foundation, depending on the roof structure can be used in the form of independent foundation or strip foundation. The foundation can be connected to the support column by embedding the anchor bolt or by embedding the column directly into the concrete foundation. The flat roof bracket does not damage the waterproof layer of the roof surface, and has the characteristics of flexible structure, convenient installation and strong reliability.

3. Ground bracket

The ground bracket is divided into three categories: single column bracket, double column bracket and single ground column bracket.

The single column support means that the support is supported by a single row of columns, and each unit has only a single row of support foundation. The support of a single column is mainly composed of a column, diagonal support, guide rail (beam), component press block, guide rail connector, bolt washer, nut slider, etc. The column is made of C-shaped steel, H-shaped steel or square steel pipe. Single column support can reduce the amount of land construction, suitable for complex terrain areas.

The double column support is in the form of front and rear columns, which are mainly composed of front column, rear column, diagonal support, guide rail (beam), rear support, component press block, guide rail connector, bolt washer, nut slider, etc. According to the size of the square array, the column is made of C-shaped steel, H-shaped steel, square steel pipe, round steel pipe and other materials. Other parts are made of C-shaped steel, aluminum alloy, stainless steel and other materials as required. The double column support has uniform force, simple processing and production, and is suitable for flat terrain areas.

Single column support refers to the support form of a square array unit support with only one column. Since the entire array has only one column, the number of photovoltaic modules that can be arranged on a single set of shelves is limited, generally 8, 12, 16, and so on. The single-ground column bracket is mainly composed of column, longitudinal beam, guide rail (beam), component press block, guide rail connector, bolt washer, nut slider, etc. The column can be made of steel pipe, prefabricated cement pipe, etc. The longitudinal beam and beam are generally made of square steel pipe due to the overhang, and the guide rail is made of C-shaped steel or aluminum alloy. This kind of support is suitable for areas with high groundwater level and rich ground vegetation.

4. Water surface bracket

With the continuous advancement of distributed photovoltaic power generation projects, making full use of surface resources such as sea, lakes and rivers to install distributed photovoltaic power stations, and implementing new forms of photovoltaic agriculture such as fish-light complementarity is another way to solve the problem that photovoltaic power generation is limited by land resources. The floating bracket is made of two parts: the float bracket and the bracket, as shown in Figure 1-3. The float is made of high-strength materials and connected design, with good stability and strong impact resistance, which can effectively prevent the damage of photovoltaic modules caused by various currents and strong winds. The bracket is generally made of stainless steel, aluminum alloy and other materials with strong corrosion resistance.

Related News